S-STUD®

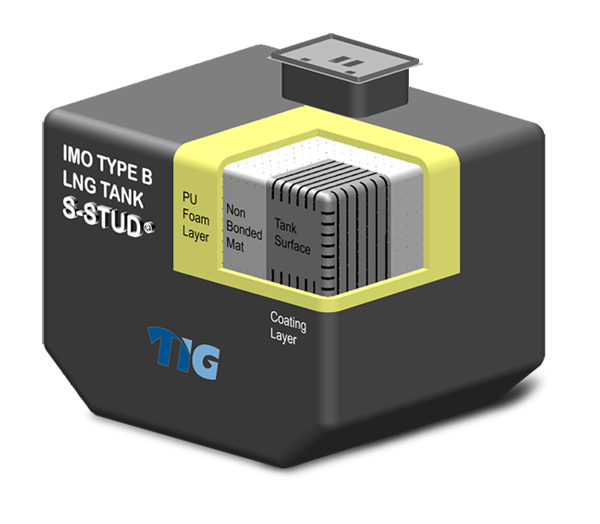

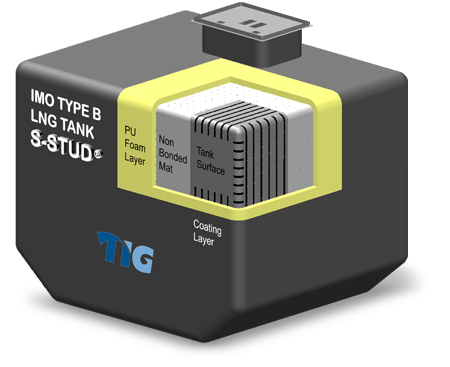

TIG KOREA’s composite spray foam insulation is designed as a non-bonded system that effectively accommodates the thermal contraction and expansion behavior unique to LNG cargo and fuel tanks.

The S-STUD® system offers broad compatibility with various tank geometries and containment types (Type B, and C tank) and can be tailored with a selection of cladding options to suit project-specific requirements.

With over 30 years of engineering expertise in cryogenic insulation, S-STUD® exemplifies TIG KOREA’s dedication to performance, durability, and continuous innovation.

S-STUD® Insulation System

- 01Non-Bonded System

- The S-STUD® concept is a non-bonded insulation system that is mechanically anchored to the tank structure. This design significantly reduces structural stress and eliminates the risk of stress-induced cracking or delamination between the foam and tank surface—common issues in bonded systems. These risks become more pronounced with thicker insulation layers and lower service temperatures.

- 02Anchoring System

- A highly robust anchoring system forms the backbone of the insulation structure, ensuring exceptional stability. This design effectively prevents cracking and other structural failures typically encountered during transient phases such as tank cooling and warming cycles.

- 03Leakage Detection System

- An integrated continuous inter barrier space between the insulation layer and tank surface acts as a dedicated gas detection channel. This allows for early identification of cryogenic liquid leaks and ensures safe containment and controlled disposal of any leaked substrate.

- 04Seamless Polyurethane Spray Insulation System

- An advanced insulation technique that reduces boil-off rates by using seamlessly spray-applied polyurethane foam, reinforced with a durable polyurea coating. This system delivers excellent thermal performance and durability

S-STUD® :

Proven Advantages Over Panel and General Spray Insulation

TYPE B

TYPE B

TYPE C

TYPE C

| Item | S-STUD® Insulation | Panel Insulation | General Spray Insulation |

|---|---|---|---|

| Type | Non-Bonded | Non-Bonded | Bonded |

| Workability | Less prefabrication time and significantly reduced installation time compared to conventional panel type insulation systems | Long prefabrication time and requires significant storage area at the shipyard | Less prefabrication time and significantly reduced installation time compared to conventional panel type insulation systems |

| Heat Ingress | Less heat ingress compared to conventional panel type insulation systems | Larger heat ingress due to joint between each panel | Less heat ingress compared to conventional panel type insulation systems |

| Crack/Delamination | Strong in terms of crack and delamination; minimized load and thermal stress | Higher risk of crack and delamination in panel joints | Weak in terms of crack formation as it is bonded to the tank surface |

| Delamination | Strong in terms of delamination | Strong in terms of delamination | Weak in terms of delamination |

| Leak Protection/Detection | Enhanced leak protection / detection through a continuous annular space throughout the whole tank surface | Enhanced leak protection / detection through a continuous annular space | Limited leak protection / detection through a channel-like annular space |

Key Features of the S-STUD®

01

Optimized application time at the shipyard

02

Improved weather exposure resistance during assembly

03

Robust UV and seawater resistance (Deck tanks)

04

Improved insulation shelf-life time

05

Streamlined and enhanced quality application

06

Excellent thermal efficiency

07

Highly resistant to fire (DIN 4102 Part1, class B2 or higher)

Reference.